how to measure galvanized thickness|galvanized coating thickness standard pdf : mfg There are two methods for measuring the zinc coating thickness of hot-dip galvanized steel; a magnetic thickness gauge and optical microscopy. The simplest and non-destructive way is to utilize a magnetic . 20 de dez. de 2023 · Press the Xbox button to open the guide. Select Profile & system > Settings > General > Network settings. Check your settings again to make sure the .

{plog:ftitle_list}

WEBSinopse de Talvez a sua jornada agora seja só sobre você: falar sobre a nossa jornada é falar também sobre aquele medo de dar os primeiros passos pra seguir em frente, sobre tudo o que a gente sente ao longo .

Methods for Measuring Galvanizing Weight or Thickness. Coating weight or thickness can be measured by one of four methods. Stripping, Microscopy, . There are two methods for measuring the zinc coating thickness of hot-dip galvanized steel; a magnetic thickness gauge and optical microscopy. The simplest and non-destructive way is to utilize a magnetic .

There are two different methods used to measure the coating thickness of hot-dip galvanized steel: a magnetic thickness gauge and optical microscopy. The first method, utilizing a magnetic thickness gauge, is a non . The coating thickness must be measured, the coating peeled off, and the steel substrate thickness measured with a gauge capable of reading to the nearest tenth of an inch .There are three ways to measure the thickness of paint over galvanized steel . Adjust to zero on the zinc surface before painting. Use an electronic magnetic gauge such as the PosiTector 6000 F2 and “zero” it on the surface of the zinc. .

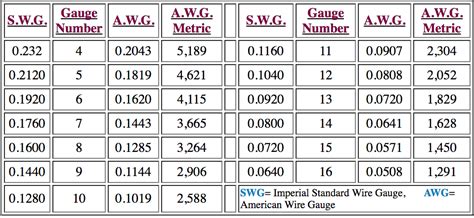

Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. . The Manufacturers' Standard Gage provides the thicknesses for standard steel, galvanized steel, and stainless steel. The Brown and Sharpe Gage, also known as the American Wire Gage (AWG), is used for .In addition to steel thickness, the composition of the steel alloy itself is also relevant. Silicon which is used to deoxidise steel will affect coating thickness too: the more silicon present, the more reactive the zinc and the greater the .

When measuring a galvanised item, if there are sections of the item which have differing steel thicknesses, each thickness range shall be treated as a separate article. The thickness ranges are dictated by AS/NZS 4680, Table 1 and .

Place your measuring tape perpendicular to the sheet metal so you can measure its thickness correctly. After obtaining the measurement in millimetres, you can convert it to inches by multiplying the value in millimetres by 0.03937. After you obtain either measurement, compare the value with those on a sheet metal gauge of the appropriate .that it is difficult to directly measure the thickness accurately. For example, a G90 coating contributes about 1.6 mils (0.0016 inches, or about 42 microns) to the total thickness of the coated sheet. For . galvanized and galvannealed sheet, 55% aluminum-zinc alloy-coated sheet, and zinc-5% aluminum alloy-Gauge (Ga.) is a measurement unit of the thickness of a thin material (such as sheet metal or plastic film). We often use gauges with numbers to show the thickness or diameter of materials. . the thinner the metal sheet. For example, 16 gauge galvanized steel sheet thickness is 1.6129 mm (0.0635 inches); while 18 gauge galvanized steel sheet .

In this video we can see how to verify the galvanizing coating thickness testing . Galvanization is the process of applying a protective zinc coating to stee.

The test should also be performed multiple times to get an accurate reading of the thickness. A banana gauge is another gauge that can be used for measuring the thickness of galvanized products. The banana gauge can be used on any part of . Galvanized steel thickness varies slightly from standard steel. For example, 10-gauge galvanized steel is 0.1382 inches (3.51 mm) thick. . The concept of “gauge” as a thickness measure emerged during the American Industrial Revolution, driven by wire manufacturers’ need to quantify their products. Initially, they employed a gravimetric . Hot-dip galvanizing thickness refers to the thickness of the zinc coating after the material comes out of the hot zinc bath. Prior to being dipped in the bath, the steel goes through a preparation process to make sure the surface is metallurgically clean, which allows the zinc to adhere. . There are several ways to measure the thickness of . Contact the GalvInfo Center The usual criterion for determining the expected service life of zinc coatings is thickness: the thicker the coating, the longer the service life. Hot-dip galvanizing (batch or continuous), electrogalvanizing, zinc plating 1.7 mils (43µm) Zinc Spraying (metallizing) 1.9.

Yes. You could use an Elcometer (that's a brand of many instruments) that is typically used in a galvanizing plant to measure zinc thickness on steel, to measure the thickness of the named other coatings. Most galvanizers use a magnetic force instrument (Elcometer is one brand of several), to measure the non ferrous coating on a ferrous substrate.

PosiTector 6000 FNDS. DeFelsko’s PosiTector 6000 FNDS coating thickness gage non-destructively measures the individual thicknesses of both the paint and the zinc galvanize layers in a duplex coating system with a single reading. How Duplex Coatings Protect Steel from Corrosion. Steel corrodes when an electrolyte connects anodes and cathodes on a steel surface. mils = µm x 0.03937 oz/ft² = µm x 0.02316 g/m² = µm x 7.067 It’s important to remember that microns (µm) and coating grade have the same value. We can multiply 75 by 0.03937 to get required mils (2.95), multiply 75 by 0.02316 to get ounces per square feet [oz/ft²] (1.74), or multiply 75 by 7.067 to.steel is directly proportional to the thickness of the zinc coating. Coating thickness is an important requirement in the specification and effectiveness of hot-dip galvanizing as a corrosion protection system. However, measuring coating thickness is only one of the many specification requirements in the inspection process.

The reason for this is that measuring thickness correctly and precisely is challenging. A G90 coating, for example, adds around 1.6 mils (0.0016 inches, or 42 microns) to the total thickness of the coated sheet. .

They provide essential information about the thickness of the sheet metal to help you choose the perfect measurement for your design. For this reason, understanding how to read and use the gauge chart is vital. .

sible when parts are bent cold before galvanizing. A minimum bend radius of three times the section thickness will promote optimum galvanized coating properties (refer to ASTM A143, Standard Practice for Safeguarding Against Embrittlement of Hot-Dip Galvanized Structural Steel Products and ProcedureGauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the number, the smaller the diameter, and now it is also used to indicate the thickness. For instance, let’s say you wrapped your lucky shoelace around the pipe and marked the circumference on the shoelace. Comparing your shoelace to a measuring tape, you found the length of the string circumference is almost 7-1/2″.. 7-1/2″ ÷ pi (or 3.1415) = 2.38″ Outside Diameter.

To accurately measure the thickness of a sheet metal, you will need a caliper or micrometer, a ruler or tape measure, and a flat surface to lay the sheet on. Make sure your measuring tools are clean and in good working condition before starting. When we measure chain link “fabric” or “mesh,” we use gauge. The term “gauge” (ga) is a centuries old measure of thickness. Generally speaking, there are 3 different gauges for galvanized chain link available at our shop: 11ga, 9ga, and 6ga. One of the strangest and most important things to know about chain link gauges is the higher . Metal pipe gauge refers to the standardized measurement of the thickness of a metal pipe. It is commonly denoted by a numerical value, with lower gauge numbers indicating thicker pipes. . galvanized thickness, and galvanized structural plate thickness. The nominal gauge values range from 8 to 22. Material: Gauge 22: Gauge 20: Gauge 18: Gauge .

Coating Thickness Measurement Solutions Option #1. The PosiTector 6000 F Microprobe series consists of 3 gages which measure coatings up to 45 mils (1150 microns) thick, making them ideal for non-destructive measurement of most coatings on as low as 80 mil diameter (14 gauge) ferrous wires. For best results on small diameters, a quick release . Step-by-Step Measurement Process. Determine the Type of Pipe: Identify whether it’s copper, HDPE, PEX, steel, or another material. Outer Diameter (OD): Measure the outer diameter accurately using a measuring tape or caliper for pipes like copper and steel. Wall Thickness: Measure the thickness of the pipe’s walls. This step is crucial for . A. Hi Hendri. Readers will offer their suggestions based on their experiences, but as a preface we should add that even though you would like to simplify, a single device may not be best for all applications: galvanizing is conductive whereas anodizing is not; galvanizing is done on steel, which allows magnetic thickness testing, not so with anodizing which is done .

zinc coating thickness measurement

A gauge is a unit of measurement used to measure the thickness of a flat sheet of metal. The gauge chart—a handy chart for converting gauges to other units of measurement—generally runs from 0 to 38, though it varies depending on the kind of metal used. The higher the number, the thinner the metal, and vice versa. The Gauge Chart

brennenstuhl feuchtigkeitsmessgerät-werte erklärung

bresser feuchtigkeitsmessgerät flackern

WEBTrês empregadas domésticas que por um golpe do destino acabam na mesma cela de delegacia e decidem mudar o seu destino. 2012 · T · Novela , Conteúdo com Legendas Descritivas (LSE) Trailer. Partilhar.

how to measure galvanized thickness|galvanized coating thickness standard pdf